That’s why it’s important to readjust the belt tension at that time. Afterwards, it’s a good idea to check the belt tension every 6 months to maintain peak performance.

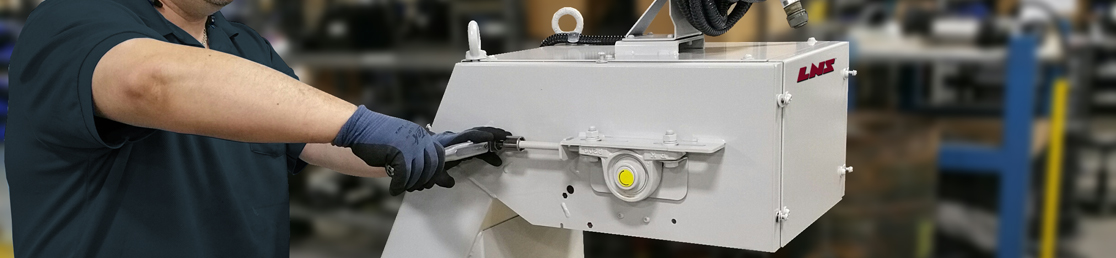

Fortunately, this is a quick and easy procedure that chip conveyor owners can easily do themselves, without a visit from a service technician. Here’s how to perform this operation on all LNS chip conveyors:

- Remove the covers at the discharge end of the conveyor to expose the pillow blocks that apply tension to the belt.

- Loosen the bolts that hold the pillow blocks in place.

- Consult the manual for your specific conveyor model for the proper amount of tension to be applied to the belt. For example, on most smaller conveyors the appropriate tension is 25 inch-pounds.

- On one side of the conveyor, adjust the pillow block bolt using a torque wrench to set the proper amount of tension, per your product manual.

- On the opposite side of the conveyor, move the pillow block into exactly the same position as the pillow block on side one, so that the drive shaft keeps the belt perpendicular to the conveyor frame to insure proper belt motion. Again, use the torque wrench to secure the pillow block bolt at the prescribed tension.

- Replace the covers, and you’re good-to-go.

Like other preventative maintenance procedures, maintaining proper belt tension will keep your LNS chip conveyor running trouble-free for a long, long time.

To learn more about chip conveyors and other that optimize machine tool performance, call 513-528-5674 or your LNS representative.