On the other hand, the benefits of regular maintenance are many:

- Workers spend their time machining workpieces, not fixing broken equipment or waiting for repair parts to arrive

- No overtime needed to catch up on deliveries

- Well maintained machines last longer, so you save capital dollars

- You prevent a failed part from causing secondary damage to other components and increasing repair costs

- Machines that are properly maintained are less likely to produce bad parts and waste material

Few would argue with the advantages of regular maintenance, but under the pressure to get work out the door it’s easy to let things slide. That’s why it’s important to put a formal preventative maintenance program in place. Here are some actions you can take to get started:

- Prepare: Consult the manufacturer’s maintenance manuals for each piece of equipment. There you’ll find a list of items to be checked and/or serviced along with the time frames for each. From this information you can create a daily, weekly, monthly checklist for machine operators to follow.

- Educate your staff about the importance of following the maintenance program and walk them through the program steps.

- Hold accountable. Assign responsibility for performing preventative maintenance and provide checklists (paper or electronic) that the employee must sign and turn in.

- Keep replacement parts on hand. Normal wear-and-tear items that are part of the normal maintenance program should be readily available on the premises. Less used replacement parts can be ordered as the time to replace them comes near. Be sure you work with OEMs that have plentiful stocks of replacement parts and readily available service technicians, if needs arise.

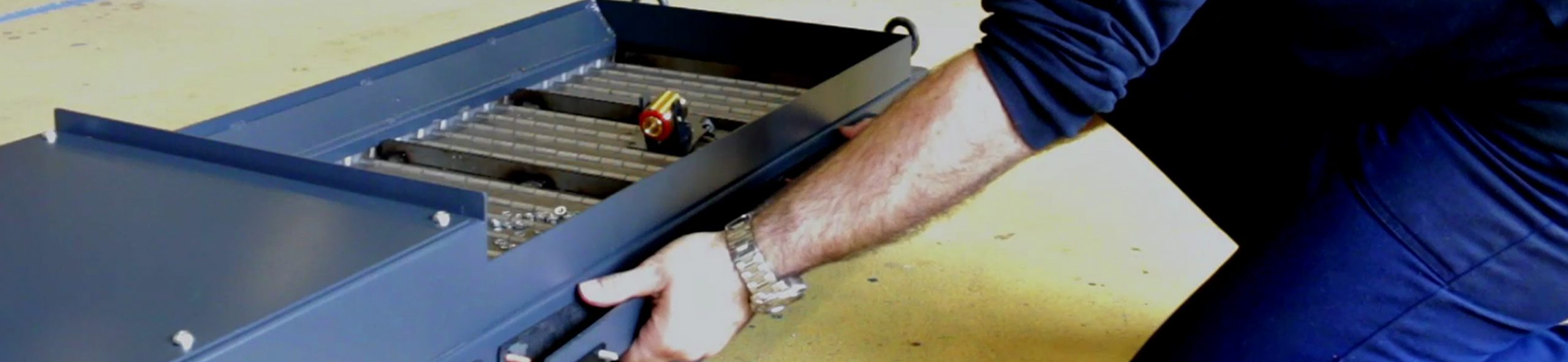

- Don’t forget peripherals. Most likely your first concerns are your CNC machine tools. However, maintaining bar feeders, chip conveyors, coolant management systems and other peripheral equipment is equally important.

LNS designs, builds, and stands behind every bar feeder, chip conveyor, steady rest system and mist collector it sells. Replacement parts and local support is just a phone call away. Contact your local LNS representative or phone: 513-528-5674 for full details.